In Summary

This apprenticeship is a two-year programme delivered by Atlantic Technological University (Galway and Sligo), Technological University of the Shannon: Midwest (Limerick), Munster Technological University (Cork), Atlantic Technological University (Sligo), and Dundalk Institute of Technology.

The Manufacturing Technician supports manufacturing operations by troubleshooting equipment and process issues. They assist with validation and qualification activities by creating and maintaining the necessary documentation for equipment, processes, and product releases.

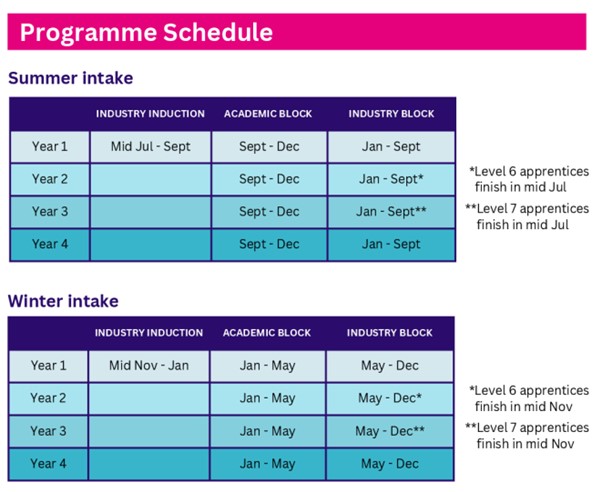

It involves two 15-week blocks of off-the-job training in the allocated institute of technology and the remaining 70% of time training on-the-job.

On successful completion of the Manufacturing Technology apprenticeship the apprentice is awarded a Higher Certificate Engineering (Level 6) Manufacturing Engineering.

To register your interest, click here.

View the Manufacturing Engineering Apprenticeship Brochure below for more details on the programme.

Employers

- View the Employer Manufacturing Handbook here.

- View the benefits of hiring a Manufacturing Engineering Apprentice here.

- View the steps on how Employers can get involved here.

View Occupation Profile from Apprenticeship.ie

To view full details of this occupation, view information from our Careers database for the following occupation: Manufacturing Technician

Entry Requirements

Before applying to this apprenticeship, please check that you meet all entry requirements.

The Manufacturing Technician Apprenticeship is open to school leavers, production operators, and technicians who want to train or retrain for a career in the manufacturing sector. It offers a pathway to progress through NFQ Levels 6 and 7, while gaining experience with one of the 450+ MedTech companies currently operating in Ireland.

Educational Requirements

Leaving Certificate (or equivalent)

CAO applicants - minimum 160 points, Pass (Grade O6 or better) in five leaving certificate subjects, two of which must be Maths and a language (English or Irish).

Leaving cert APPLIED is NOT suitable.

Cognate (related) QQI-FET Level 5, 6 applicants plus Leaving Certificate Maths.

Mature students (over 23 years) do not require a leaving certificate but must pass a company interview. click here for details.

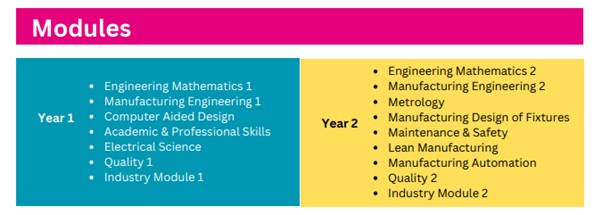

Training

In advance of completing an application for the Engineering Technician Apprenticeship it is important to understand the commitment you will need to provide to this programme.

This Higher Certificate in Manufacturing Engineering is a two-year programme, with an approved employer, with 70% of the time spent on the job and the remaining 30% spent in an allocated Technological University.

Programme Overview

The training is run by the following institutions:

Atlantic Technological University Galway

Atlantic Technological University Sligo

Technological University of the Shannon: Midwest (Limerick),

Munster Technological University Cork,

Dundalk Institute of Technology.

An enquiry or application for the manufacturing engineering apprenticeship can be made on the Manufacturing Apprenticeships website.

Skills & Qualities

An interest in working and learning in the MedTech, plastics and engineering sector.

Knowledge

Core knowledge listed:

- Quality management systems within a regulated environment (GMP)

- Raw materials, production processes, costs, and other techniques for maximizing the effective manufacturing

- Root Cause Analysis, Problem Solving, Implementing Corrective and Preventive Actions (CAPA)

- Continuous Improvement in Manufacturing (Lean manufacturing)

- Mechanics and Properties of Materials

- Mechanics and Dynamics of Machines

- Industrial Automation

- Engineering Science

- Electrical Science

- Mechanical Drawing Interpretation

- Cleanroom operations

- Metrology

- Perform routine calibration of equipment

Skills

Specialist Skills (Technical)

- Use engineering principles to make data driven decisions and apply technical judgment to product design and to continuously improve manufacturing processes

- Computer Aided Design (CAD) software to create advanced 3D models and use standard parts libraries for the selection of appropriate components required for use in manufacturing and assembly processes

- Analyse basic pneumatic/hydraulic manufacturing applications and develop automated solutions using PLC (programmable logic control) technology

- Concepts, processes and legislation for Risk Management and Health and Safety management

- Perform lean manufacturing analysis (Value Stream mapping, Overall Equipment Effectiveness, Take Time Calculation, Process Throughput measurement, 5S) to identify areas for improvement, and solve problems

- Analyse, develop and implement preventive actions which proactively resolve product, process and systems issues

- Complete industry documentation aligned to GMP (Good Manufacturing Practice) standards

- Partner with project team members to create, execute and document activities associated with equipment validation and release

- Drive the troubleshooting and corrective action effort for any process issues

- Quality assurance, safety compliance systems and quality management principles needed in manufacturing and service organisations

- Configure and operate manual, automated and ancillary production equipment required for the manufacturing process

Soft Skills:

- Time management skills;

- Creative problem solving and work as an effective group member

- Academic writing and referencing sources of information

- Proficient in both written and oral communication skill

- Apply the basic principles of critical thinking / problem solving

Competencies

- Ethics

- Communications

- Adaptability

- Teamwork

- Ability to work independently

- Reading Comprehension

- Problem solving

- Critical thinking

- Time management

- Report Writing

- Mathematics and Statistics

- Health, Safety and Environmental Awareness

- The ability for Continuous Professional Development

- Health, Safety and Environmental Awareness

- The ability for Continuous Professional Development

Work Activities

Working as a team member to provide a technical service to produce product per organisational needs in line with all safety, regulatory and organiational requirements, the work of a Manufacturing Technician includes:

- Preparing equipment, work areas and materials and ensuring/verifying readiness of manual, automated and ancillary equipment.

- Operation and technical support of manual, automated assembly and ancillary equipment.

- Troubleshooting and repair of day-to-day manufacturing issues which may impact on efficiencies, safety or quality.

- Performing routine calibration on equipment.

- Operating of measuring equipment and other advanced metrology equipment.

- Support product development, validation and improvement projects.

- Documentation of all activities in line with GMP requirements.

- Cross train within the team and training of new members.

- Ability to work on own initiative

The Manufacturing Technician will work both autonomously and cross-functionally with Production, Operations, Engineering Support, Quality, Facilities, and Safety to ensure that the engineering activities/projects are completed as per defined project schedule.

The manufacturing technician will also work in establishing and coordinating corrective/preventive maintenance activities for Production/Operations equipment within the manufacturing site.

View the National Occupational Profile here.

View the Apprenticeship Code of Practice for Employers and Apprentices here.

Career Progression

There are opportunities across the Medical Devices sector in Plastics and Engineering companies for Manufacturing Technicians.

If you are currently employed, there are several options available to support both your educational and career progression. You may be eligible for promotion within your current company. With your existing qualifications and experience, you could apply for more senior roles in other companies. Alternatively, you might also consider starting your own business using the skills and knowledge you've already gained.

As a Level 6 Manufacturing Technician, you can:

- Progress to Level 7 programmes in areas such as manufacturing, engineering, quality, or design—often supported by your employer’s educational funding.

- Apply for roles in manufacturing, engineering, or quality assurance—both within your current organisation and across companies in sectors like medical technology and engineering.

- Progress to full qualifications on the NFQ at Levels 7–10

- Pursue a partial award - upskill in a specific area through short, specialised courses

- Apply for technical roles in areas such as Maintenance or Quality.

- Specialise further through part-time, modular Level 7 programmes in:

- Precision engineering

- Polymer engineering

- Quality engineering

Lifelong Learning

Education is a lifelong journey. No matter your age, you can always choose to upskill or retrain to stay competitive and open up new opportunities.

After completing an apprenticeship, you may have the opportunity to continue your education with full qualifications at NFQ Levels 7 to 10. Alternatively, you can pursue a partial award or enhance your skills in a specific area by taking a short, specialised course.

As a Level 6 Technician, you can progress to a Level 7 apprenticeship programme or explore other part-time Level 7 manufacturing and engineering programmes through in-company educational support. You may also choose to apply for technical roles in departments such as Maintenance or Quality, and specialise further by enrolling in modular, part-time Level 7 programmes in areas like precision engineering, polymer engineering, or quality engineering.

Useful Links: Educational

- Springboard & conversion courses

- Skillnet sector learning network courses

- Local ETB Board: Skills to advance

- Search Post Graduate options

Enterprise and Self-Employment Support:

On completion of the apprenticeship you may decide to set up your own business. The links below might be useful to support you:

- Local Enterprise Offices For profit Local enterprise support

- Local Area partnerships For profit enterprise support

- Social entrepreneurs Not-for-profit enterprise support

- Franchising Developing your business under an established franchise

Getting this Apprenticeship

To become an apprentice in Ireland you must be hired by a SOLAS-approved employer. Apprenticeship employers are formally approved by SOLAS in advance of employing apprentices. Apprentices get a formal contract of employment as part of their apprenticeship.

To find an apprenticeship, you can search apprenticeship vacancies and a list of currently approved apprentice employers on the Apprenticeship Jobs & Employers Portal. You can search for vacancies by location and employer in each apprenticeship.

Explore a list of Approved Employers by Region and by Apprenticeship type here.

This apprenticeship is managed by the Irish Medtech Association. If you are interested in a Manufacturing Technology Apprenticeship you should contact the Irish Medtech Association via the contact details below.

Full eligibility criteria for this apprenticeship are available in the Manufacturing Technology Apprenticeship brochure.

Further information is also available from the industry lead for this apprenticeship:

Irish Medtech Association

IBEC

84-86 Lower Baggot Street

Dublin 2

Tel: +353 1 605 1727/ 087 715 7967

Email: [email protected]

Website: www.manufacturingapprenticeships.ie

LinkedIn: www.linkedin.com/company/manufacturing-apprenticeships

You can send an enquiry or apply for this apprenticeship on the Manufacturing Apprenticeships website.

Finding an Employer

Finding an employer or registering your interest with an official Coordinating Provider is one of the first things you need to do to start an apprenticeship.

To find an apprenticeship and secure an apprenticeship work contract you can search apprenticeship vacancies on the Apprenticeship Jobs Portal . You can search for vacancies by location and by apprenticeship type.

Your local Education and Training Board may also hold details of employers seeking to employ an apprentice.

You should also directly connect with local employers who might be interested in taking on an apprentice. It is a great idea to get a part time job with a local employer who might be more inclined to take you on as an apprentice following a successful work experience placement or a part time job contract.

Further information about this apprenticeship may be available from the following organisations on this website:

Organisations supporting this apprenticeship

Where we know of supporting organisations we list these below:

Online Job Sites

Here are some direct links to employment websites that frequently list apprenticeship vacancies.

Note: These websites may include vacancies that are not QQI accredited Apprenticeships.

Pay & Fees

As an apprentice, you earn while you learn. The employer pays you a salary while you are being trained on-the-job and off-the-job. The rate of pay is agreed between you and your employer.

Apprentices complete their off-the-job training in a higher education institution, for which they are required to pay a student contribution.

The amount payable is a proportion of the annual student contribution for students attending a full-time course in higher education. The student contribution is paid directly to the higher education institution over the two years.

Manufacturing Technology

| Year 1 | €1,500 |

| Year 2 | €1,500 |

| Total Fee | €3,000 |

.png)