In Summary

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2024]. Proposed launch July to September 2024.

Precision engineering is involved with the design, manufacturing, and measurement of highly specified parts for the medical, aerospace, automotive, oil and gas exploration and related industry. This Level-6 apprenticeship has been designed with industry to respond provide a highly skilled and valued programme in the advanced manufacturing industry.

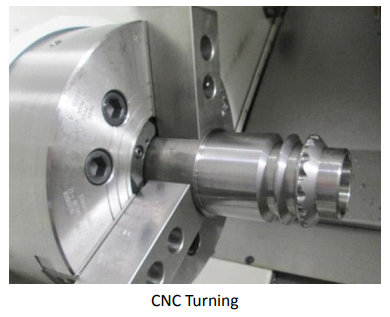

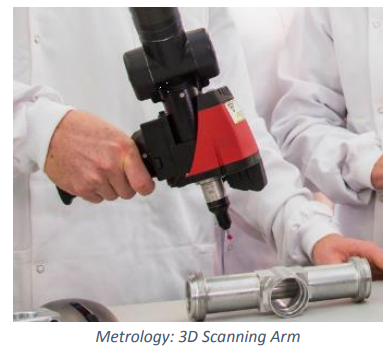

Apprentices will learn how to work effectively with both manual and CNC machines to produce parts from an initial design to a final product. Parts are designed using CAD systems to develop solutions to engineering problems and when manufactured the accuracy will measured using specialised measurement equipment such as co-ordinate measuring machines (CMM).

Learners will work as individuals and in groups on a variety of industrial standard engineering projects.

View Occupation Profile from Apprenticeship.ie

To view full details of this occupation, view information from our Careers database for the following occupation: Precision Machinist & Quality Control

Entry Requirements

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2023]. proposed launch July to September 2023.

Provisionally:

Further Education Opportunities.

Apprentices can progress to Level 7 and Level 8 Engineering programmes subject to meeting the entry requirements. Entry to TUS Precision Engineering degree programmes at advanced level will be on a case-by-case basis but applications are encouraged. Minimum Entry Requirements Leaving Certificate: A minimum of 5 Passes in Leaving Certificate subjects, including Mathematics and English/Irish.

Candidates applying as mature applicants will be required to attend an interview and may be requested to take an aptitude test to prove their suitability for a place on this programme.

Advanced Entry to this Apprenticeship Candidates who hold a relevant qualification and/or certification with appropriate endorsements or examination attainments in a cognate area can be considered for advanced entry subject to a satisfactory interview.

Training

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2024]. proposed launch July to September 2024.

Provisional Programme Structure

Stage 1: Employer recruitment and registration ● On-the-Job Induction

Stage 2: Block release to Education (15 weeks) ● Introduction to Computer Aided Design ● CNC Machining, Programming and Setting; Milling ● Communications & Computing ● Introduction to Measuring Equipment and Quality Control ● Engineering Workshop Technology and Practice ● Introduction to Engineering Maths and Engineering Science

Stage 3: Industry Based 1 ● On-the-Job education

Stage 4: Block release to Education (15 weeks) ● Computer Aided Design for Machining ● Multi Axis machining and Programming ● CAM Programming and Operation ● Metrology and Quality Control ● Engineering Maths ● Engineering Science

Stage 5: Industry Based 2 ● On-the-Job education

Stage 6: Block release to Education (15 weeks) ● CAD and Additive Manufacturing ● Multi Axis machining and Programming o 5 axis machining o Robotics o Wire EDM o CAM Programming and Operation ● Metrology and Six Sigma ● Applied Engineering Maths

Stage 7: Industry Based 3 ● On-the-Job education and Project work.

Skills & Qualities

This is a practical job that would suit you if you like machinery and enjoy working with your hands.

Mathematical ability is essential because the work involves making accurate calculations, measurements and machine adjustments.

You'll need to be able to read and understand engineering drawings, and follow written and verbal instructions, which may be on a computer terminal.

You should be able to understand technical drawings.

You also need to have good computer skills and good eye sight.

You need to have a methodical approach to your work, and good organisational skills.

Patience and accuracy are essential for setting up and operating the machines.

Engineering craft machinists should be able to work well without supervision and also enjoy being part of a team. You will need to develop good hand to eye co-ordination.

You'll spend much of your time on your feet, so you should be physically fit.

Work Activities

Features of the programme

● Learn while earning. Industry based apprenticeship paid work.

● Work and learn on world class equipment, software, and projects.

● Industry level skills and knowledge.

● Build your knowledge from the basics to complex processes through high practical content in manual and CNC Machining.

● Uses industrial equipment to solve real industrial problems; 5 axis machining, Twin spindle lathe work with driven tooling, high speed machining strategies.

● Metrology and Six Sigma content aligned to the ASQ Yellow and Green belt qualifications.

● Allows for maximum learning and self-development; work offline and develop skills, knowledge, and competence.

● Develops a deep knowledge of materials, design, and manufacture through the utilisation of modern technology.

● Developed in conjunction with world class companies in response to a shortage in highly skilled precision machinists

● Additive manufacturing and CAD

● Robotics and Automation in CNC machining

● Progression to Level 7 and 8 programmes within Technical University of the Shannon and other colleges/universities.

- Calculate dimensions or tolerances, using instruments such as micrometers or vernier calipers.

- Machine parts to specifications, using machine tools, such as lathes, milling machines, shapers, or grinders.

- Set up, adjust, or operate basic or specialised machine tools used to perform precision machining operations.

- Align and secure holding fixtures, cutting tools, attachments, accessories, or materials onto machines.

- Measure, examine, or test completed units to check for defects and ensure conformance to specifications, using precision instruments, such as micrometers.

- Monitor the feed and speed of machines during the machining process.

- Maintain machine tools in proper operational condition.

- Study sample parts, blueprints, drawings, or engineering information to determine methods or sequences of operations needed to fabricate products.

- Operate equipment to verify operational efficiency.

- Check work pieces to ensure that they are properly lubricated or cooled.

Career Progression

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2024].

Proposed launch July to September 2024.

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2023]. Proposed launch July to September 2023.

Graduates will typically be employed in one of the following roles in the medical device, human implant, and Life Sciences Industries:

● Precision machinists with multi axis machining work

● CAD Design technicians in manufacturing

● CNC machinist and programmer

● Materials selection and processing.

● Process measurement and control

● Equipment test engineer/technician

● Project Implementation

● Additive Manufacturing

● Six Sigma and Continuous Process improvement

● Metrology and Quality Control

Getting this Apprenticeship

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2024]. Proposed launch July to September 2024.

To find an apprenticeship, you can search apprenticeship vacancies and a list of currently approved apprentice employers on the Apprenticeship Jobs & Employers Portal. You can search for vacancies by location, and employers in each apprenticeship.

Use this link to explore a list of Approved Employers by Region and by Apprenticeship type.

Contact Information For further information contact:

Head of Department, Programme Leader, Dr. Philip Ryan, Mr. Ciarán O’Loughlin Moylish Campus Moylish Campus

Email: [email protected] Email: [email protected]

Tel: - 061- 293242 Tel: - 061-293339

Technical University Apprenticeship programmes

Finding an Employer

Finding an employer or registering your interest with an official Coordinating Provider is one of the first things you need to do to start an apprenticeship.

To find an apprenticeship and secure an apprenticeship work contract you can search apprenticeship vacancies on the Apprenticeship Jobs Portal . You can search for vacancies by location and by apprenticeship type.

Your local Education and Training Board may also hold details of employers seeking to employ an apprentice.

You should also directly connect with local employers who might be interested in taking on an apprentice. It is a great idea to get a part time job with a local employer who might be more inclined to take you on as an apprentice following a successful work experience placement or a part time job contract.

Pay & Fees

This Programme is in Development with PTMA-Precision Turned Parts Manufacturing Association and TUS Midwest [Moylish campus in 2024].

Proposed launch July to September 2024.