Work Environment

Engineering Technician - Mechanical s typically work in the following Career Sectors:

Videos & Interviews

Combilift, OEM Engineering Traineeship

The Original Equipment Manufacturing (OEM) Engineering Traineeship prepares Trainees for work as future Engineers/Technicians and combines theory and practical industry experience to provide a basic understanding of Manufacturing and Engineering Processes. The Trainee will complete 26 weeks classroom-based learning in Monaghan Institute and 12 weeks work placement in Combilift spread out over the course of the 9 months.

Combilift, OEM Engineering Traineeship

The Original Equipment Manufacturing (OEM) Engineering Traineeship prepares Trainees for work as future Engineers/Technicians and combines theory and practical industry experience to provide a basic understanding of Manufacturing and Engineering Processes. The Trainee will complete 26 weeks classroom-based learning in Monaghan Institute and 12 weeks work placement in Combilift spread out over the course of the 9 months.

Videos on the Web

- Engineering Technician - Mechanical - from: Youtube Search

- Mechanical Engineering Technician - from: YouTube Video

Most commonly reported Work Activities

- Getting Information Observing, receiving, and otherwise obtaining information from all relevant sources.

- Evaluating Information to Determine Compliance with Standards Using relevant information and individual judgment to determine whether events or processes comply with laws, regulations, or standards.

- Communicating with Supervisors, Peers, or Subordinates Providing information to supervisors, co-workers, and subordinates by telephone, in written form, e-mail, or in person.

- Updating and Using Relevant Knowledge Keeping up-to-date technically and applying new knowledge to your job.

- Drafting, Laying Out, and Specifying Technical Devices, Parts, and Equipment Providing documentation, detailed instructions, drawings, or specifications to tell others about how devices, parts, equipment, or structures are to be fabricated, constructed, assembled, modified, maintained, or used.

- Processing Information Compiling, coding, categorising, calculating, tabulating, auditing, or verifying information or data.

- Interpreting the Meaning of Information for Others Translating or explaining what information means and how it can be used.

- Documenting/Recording Information Entering, recording, storing, or maintaining information in written or electronic/magnetic form.

- Making Decisions and Solving Problems Analysing information and evaluating results to choose the best solution and solve problems.

- Organising, Planning, and Prioritising Work Developing specific goals and plans to prioritise, organise, and accomplish your work.

The Work

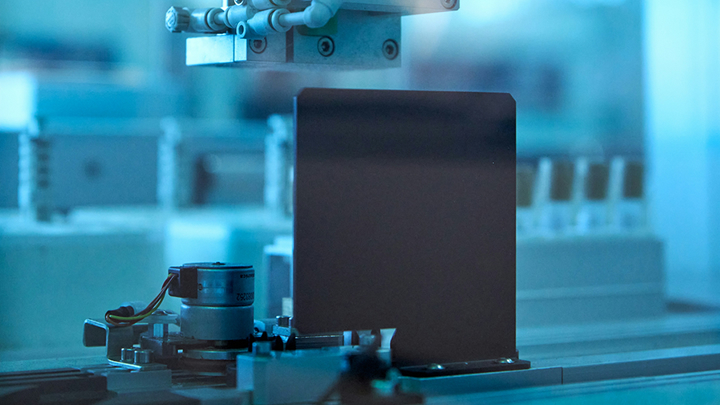

Many engineering technicians are involved in continuous production for manufacturing industries, where they develop, operate and maintain the mechanical processes that control activities such as mixing raw materials or labelling finished products.

They work in many sectors including:

- Manufacturing: constructing engine and gear compartments, building and maintaining conveyer equipment.

- Power and Processing: designing and making industrial plant machinery.

- Building Services: servicing lifts and escalators.

- Transport: repairing components on rail engines and signalling equipment.

They may begin each job by planning the assembly and production systems, thinking carefully about issues such as materials, costs and efficiency. Some technicians are responsible for purchasing raw materials and parts, and making sure that they are available on time.

Once they have installed the machinery, mechanical engineering technicians monitor production and inspect and test products to make sure they have been correctly manufactured and are capable of performing to the required specification. This may involve calculating and assessing the results of quality control tests.

Mechanical engineering technicians plan and operate maintenance programmes to service machinery, and provide technical guidance in diagnosing and repairing faults in industrial equipment and instruments. Technicians may estimate and cost products, or parts of products, to meet customers' requirements. Mechanical engineering technicians support the work of engineers across a very wide range of activities.

For example, they may help engineers to design and develop cars that are more economical on fuel, test jet engines, develop agricultural equipment or maintain the systems used on offshore oil and gas platforms. They help to develop and test the latest information and telecommunications technology, including the Internet, mobile telephones and games consoles.

Some engineering technicians may use their knowledge to help sales and marketing departments. Mechanical engineering technicians may lead teams made up of other technicians and craft workers.

Most commonly reported Work Tasks

- Calculate required capacities for equipment of proposed system to obtain specified performance and submit data to engineering personnel for approval.

- Review project instructions and blueprints to ascertain test specifications, procedures, and objectives, and test nature of technical problems such as redesign.

- Draft detail drawing or sketch for drafting room completion or to request parts fabrication by machine, sheet or wood shops.

- Analyse test results in relation to design or rated specifications and test objectives, and modify or adjust equipment to meet specifications.

- Record test procedures and results, numerical and graphical data, and recommendations for changes in product or test methods.

- Read dials and meters to determine amperage, voltage, electrical output and input at specific operating temperature to analyse parts performance.

- Review project instructions and specifications to identify, modify and plan requirements fabrication, assembly and testing.

- Set up and conduct tests of complete units and components under operational conditions to investigate proposals for improving equipment performance.

- Set up prototype and test apparatus and operate test controlling equipment to observe and record prototype test results.

- Evaluate tool drawing designs by measuring drawing dimensions and comparing with original specifications for form and function using engineering skills.

Further Information

- Engineering Technician - Mechanical - from: N.C.S. [UK]

- Engineering Technician - Mechanical - from: N.C.S. [UK]

- Engineering Technician - Mechanical - from: N.C.S. [UK]

Qualities - Engineering Technician - Mechanical

You must have strong technical and practical skills. You will need to develop a logical, accurate and methodical approach to your work.

Technicians also need strong communication skills, to work with other technicians and engineers. Technicians need the ability to read and interpret technical drawings and plans, and to explain them to others. You must be able to work methodically and precisely. You must have an aptitude for maths, science and IT.

Mechanical engineering is a very fast-changing area; it is at the leading edge of research and technology. You must therefore be willing to learn and develop new knowledge, to keep pace with advances in ideas and technology.

You may be responsible for staff, so the ability to lead and motivate others is an advantage.

Your work could involve contact with customers, so you will need the ability to explain products and technology clearly to people who may not have technical knowledge.

Interests - Engineering Technician - Mechanical

This occupation is typically suited for people with the following Career Interests:

Realist

Realists are usually interested in 'things' - such as buildings, mechanics, equipment, tools, electronics etc. Their primary focus is dealing with these - as in building, fixing, operating or designing them. Involvement in these areas leads to high manual skills, or a fine aptitude for practical design - as found in the various forms of engineering.

Realists like to find practical solutions to problems using tools, technology and skilled work. Realists usually prefer to be active in their work environment, often do most of their work alone, and enjoy taking decisive action with a minimum amount of discussion and paperwork.

Investigative

The Investigative person will usually find a particular area of science to be of interest. They are inclined toward intellectual and analytical activities and enjoy observation and theory. They may prefer thought to action, and enjoy the challenge of solving problems with sophiscticated technology. These types prefer mentally stimulating environments and often pay close attention to developments in their chosen field.

Entry - Engineering Technician - Mechanical

Apprenticeship Route

The official entry route for a Engineering Technician - Mechanical is through undertaking an apprenticeship.

Click here to find information on the OEM Engineering Technician apprenticeship

There are many pathways to developing your skills and readiness for a career in (OEM) Original equipment manufacturing:

Training & Development

Traineeship Engineering operations & OEM, Manufacturing NFQ level 5 search our FET coursefinder

FET Centre PLC Post leaving cert pre apprenticeship & engineering nfq level 5 search our FET centre PLC coursefinder

Higher education CAO entry Mechanical Engineering NFQ level 6-7. search our CAO coursefinder

A list of Engineering Technician accredited programmes is available from Engineers Ireland

Apprenticeship (OEM) Original equipment maufacturing NFQ level 6 search apprenticeships

This is a 3 year programme.

-

To become an apprentice in Ireland you must be hired by an employer. Apprenticeship employers are formally approved by SOLAS in advance of employing apprentices. Apprentices get a formal contract of employment as part of their apprenticeship.

To find an apprenticeship, you can search apprenticeship vacancies on the Apprenticeship Jobs Portal. You can search for vacancies by location and by apprenticeship.

Your local Education and Training Board may hold details of employers seeking to employ an apprentice.

This apprenticeship is managed by Cavan and Monaghan ETB (CM ETB). If you are interested in an OEM Engineer Apprenticeship you should make contact with CM ETB via the contact details in the ‘Find Out More Section’ below.

Full eligibility criteria for this apprenticeship are available in the OEM Engineer Apprenticeship brochure.

Please note: To become an OEM engineer apprentice you must pass the Ishihara Colour Vision Test (24 Plate Edition).

Last Updated: October, 2023

Pay & Salary - Engineering Technician - Mechanical

Salary Range (thousands per year)* €35k - €75k

Salaries vary by employer, duties, role, experience, and location.

Data Source(s):

Morgan McKinley / Sigmar / Collins McNicolas/ Lincoln/ WEI

Last Updated: March, 2024

* The lower figures typically reflect starting salaries. Higher salaries are awarded to those with greater experience and responsibility. Positions in Dublin sometimes command higher salaries.

View Salary information from Indeed.ie

Note: data not aways available

Labour Market Updates - Engineering Technician - Mechanical

This information has been derived from the Solas National Skills Bulletin (2025).

Employment levels grew strongly between 2023 and 2024 (by 6,300 persons), resulting in above average annual employment growth over the five-year period. Almost half were employed in the professional activities sector with a further quarter employed in industry. At 29%, the share of non-Irish citizens was above average which is borne out in the employment permit data, with over 1,300 new permits issued in 2024 primarily for electrical, mechanical, automation and project engineers.

Skills for Growth data highlighted issues in the utilities and manufacturing sectors, particularly relating to mechanical, electrical and lead instrumentation engineers; with automation, mechanical and electrical engineers also identified as roles which were difficult-to-fill in the Recruitment Agency Survey. Experience (usually at least 2 years) was a key demand along with technical (biomedical, electrical/power engineering, life sciences etc.), finance, leadership, and digital (including data analysis and AI) skills.

These skills play a critical role in Ireland’s industrial sector, particularly in the life sciences, and in the transition to a digital and green economy. As such, demand is likely to persist for these roles. Although the supply of skills from the education and training system appears strong, the recent employment growth and the demand for specific skills and experience means that skills shortages are persisting.

Skills shortage:

Engineers (mechanical, electrical, automation)

Useful Contacts - Engineering Technician - Mechanical

-

Engineers Ireland

- 22 Clyde Road, Ballsbridge Dublin 4

- (01) 665 1300

- Click Here